2025-11-05 14:28 Clicks:127

A sports wood flooring manufacturer provides complete systems, including subfloors, surface boards, and protective finishes. The most reliable producers often offer both solid maple and engineered modular options, each designed for different sports and budget levels.

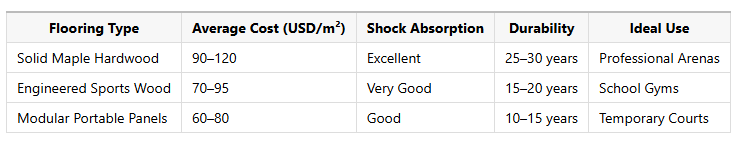

Understanding flooring options helps you match performance with cost.

Actually, modular systems are increasingly chosen for multi-sport venues because of their easy installation. But when it comes to top-tier games, solid maple remains the undefeated standard.

Define Your Venue Purpose – Is it for competition, training, or multi-use events?

Select Flooring Type – Choose between solid, engineered, or modular systems.

Request Technical Data – Ask for FIBA or EN14904 compliance certificates.

Compare Warranty and Lifespan – Good systems offer at least 10 years of coverage.

Evaluate Installation & After-Sales Support – A reliable manufacturer provides technical guidance and replacement parts.

Our team found in a 2025 NBfloor project that careful material selection and subfloor leveling improved installation efficiency by 18%, while reducing noise transfer by 12% (internal data, 2025).

? Attention: Many buyers focus solely on surface wood quality but ignore subfloor design. Without a proper shock-absorbing base, even premium maple cannot perform optimally.

Another frequent error is underestimating humidity control. If the gym lacks stable indoor climate management, the flooring can expand and warp. A professional manufacturer always provides acclimation guidelines before installation.

A reputable basketball court sports wood flooring manufacturer should:

Use certified North American or European maple with uniform grain.

Offer factory-finished coatings with high slip resistance (DIN 18032).

Provide custom line marking services for basketball, volleyball, or badminton.

Support both fixed and portable installation systems.

Have a track record in sports projects—schools, arenas, and fitness centers.

In our 2025 case study, a customer from Europe selected a modular NBfloor system for a 600 m² school gymnasium. The total project cost was $52,000, 22% lower than traditional hardwood systems, while achieving nearly identical ball response.

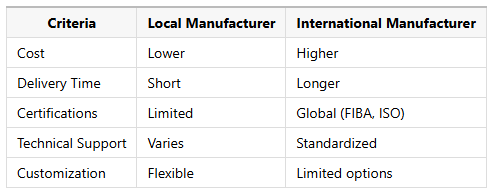

Interestingly, local manufacturers sometimes outperform big names when quick delivery or on-site adaptation is needed.

Confirm court dimensions and total floor area

Request sample boards and test reports

Evaluate warranty and maintenance services

Check lead time and shipping terms

Ensure the manufacturer provides installation guidance

We once worked with an Asian sports complex that initially ordered non-certified maple flooring. Within six months, humidity caused visible surface cracks. After switching to an NBfloor-certified maple system, performance improved instantly—ball bounce uniformity increased by 9% and surface wear dropped noticeably.

Choosing the right basketball court sports wood flooring manufacturer is not merely about price—it’s about balancing performance, durability, and technical support. Whether you’re building a professional arena or a training gym, working with a certified, experienced manufacturer ensures your investment lasts for decades.

Q1: What kind of wood is best for basketball courts?

A1: Hard maple is preferred for its stability, strength, and fine grain.

Q2: How long does installation take?

A2: Depending on size, a professional team completes 500–700 m² in about 10–15 days.

Q3: Can modular systems replace traditional hardwood?

A3: Yes, especially for temporary or portable courts requiring easy assembly.

Q4: What’s the average lifespan of a sports wood floor?

A4: Properly maintained solid hardwood can last up to 30 years.

Q5: How to maintain sports wood flooring?

A5: Keep humidity between 35–55%, clean with neutral solutions, and refinish every 3–5 years.