2025-11-07 14:14 Clicks:145

When planning a sports facility, one of the first questions people ask is: what are the materials used for sports wood flooring? The answer goes far beyond just “wood.” Each layer of the floor system — from surface to substructure — is designed to balance strength, elasticity, and safety for athletes.

A standard sports wood flooring system includes four main layers: the hardwood surface, plywood or LVL substructure, shock-absorbing pad, and moisture barrier. Together, they form a resilient surface that provides optimal ball bounce and player protection.

According to the International Sports Flooring Association (ISFA 2025), over 72% of professional indoor courts use multi-layer wood systems combining solid hardwood and engineered wood for maximum stability and durability.

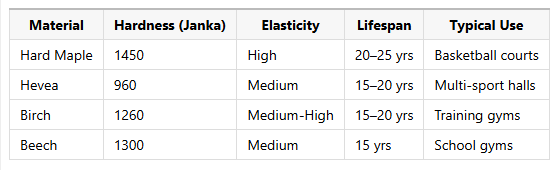

The type of material directly affects performance and lifespan. Below are the most frequently used components.

Hard maple is the gold standard for professional basketball courts. It offers consistent grain density, excellent rebound, and a smooth finish. Maple’s hardness also resists dents and scratches caused by heavy athletic use. Many top manufacturers, such as NBfloor, select Grade-A maple sourced from North America for its uniform texture and color.

Hevea is an eco-friendly alternative widely used in Southeast Asia. It is dense, moderately elastic, and cost-effective. Hevea wood flooring is ideal for training centers or multi-purpose halls that need durability without premium maple pricing.

Birch and beech are often chosen for semi-portable or hybrid sports floors. They are slightly softer than maple but offer great dimensional stability. These species are commonly used in European gymnasiums and school facilities.

Beneath the hardwood surface lies the LVL (Laminated Veneer Lumber) or plywood batten system. These engineered woods distribute impact energy evenly and prevent warping. Their layered composition enhances strength while reducing overall weight.

Placed under the substructure, these rubber or foam pads are critical for player safety. They absorb 55–70% of impact force, minimizing injuries during jumps and landings. The pad density and spacing determine the court’s comfort level.

A polyethylene or bituminous membrane acts as a moisture barrier, preventing humidity from damaging the wood. Maintaining a dry subfloor is essential for long-term performance, especially in humid climates.

Interestingly, despite its hardness, maple maintains excellent resilience, making it ideal for high-impact sports. Birch and hevea, by contrast, balance flexibility with cost, suitable for non-competition facilities.

In 2025, our engineering team collaborated with a local sports complex using NBfloor’s maple and LVL hybrid system. The final court achieved 68% shock absorption and passed FIBA’s ball rebound test on the first inspection. The key was their combination of pre-dried maple planks with LVL battens and double-layer underpads — a structure that delivered both strength and comfort.

? Attention: Many buyers assume all hardwood is suitable for sports flooring. In reality, domestic oak or pine lacks the elasticity needed for sports impact. Another mistake is ignoring moisture content. Even the best wood can warp if humidity exceeds 10–12%.

Identify the sports type and frequency of use.

Choose a certified hardwood species (maple, birch, or hevea).

Confirm wood moisture content below 10%.

Select an LVL or plywood substructure for stability.

Ensure the system includes a moisture barrier and shock pad.

Based on ISFA data (2025 edition):

Maple system: 90–130 USD/m²

Birch or Hevea system: 65–90 USD/m²

Engineered hybrid system: 80–110 USD/m²

Confirm hardwood type and origin

Check moisture content and drying method

Ask for EN 14904 or FIBA test reports

Inspect subfloor and cushion pad materials

Review warranty and expected service life

Q1: Why is maple preferred for sports flooring?

A1: Because of its dense grain, hardness, and consistent bounce, maple ensures reliable performance for professional games.

Q2: Can engineered wood be used instead of solid wood?

A2: Yes, but only if it meets sports performance standards; otherwise, flexibility and rebound may be compromised.

Q3: How thick should the surface layer be?

A3: Usually 20–22 mm for solid maple and 12–15 mm for engineered layers.

Q4: What is the role of the moisture barrier?

A4: It prevents water vapor from reaching the wood and causing swelling or deformation.

Q5: How often should the floor be resurfaced?

A5: Every 5–7 years, depending on usage and maintenance quality.